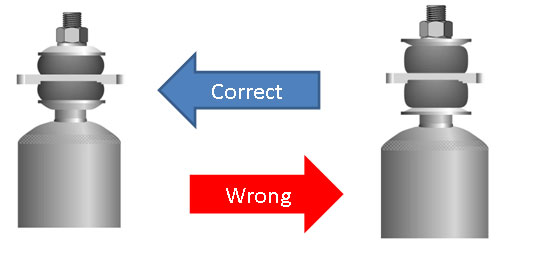

The Reagan Ind. Shock Absorber Quick Reference Application sheets use end mount codes as one of the key indicators for identifying the correct replacement shock. The five end mount codes used on these sheets are as follows:

“S” for Stud. The shock is mounted with a vertical Stud, rather than an eye ring. See figure #1

“ES” stands for E for eye ring, and S for sleeve. A steel sleeve is attached between two factory pressed in bushings. See figure #2

“ES (Ext)” is the same as “ES”, only the sleeve is extended out from the bushing. See figure #3. Note that this end mount identification is used only for the purposes of the Quick Reference Application Sheets, and is not referenced in the Gabriel catalog.

“EB2” & “EB3” E again stands for Eye ring, and B stands for Bushing. There is no sleeve. The mounting bolt fits directly into the bushings, which are held in place by washers. The Gabriel shock bushings are separate. The “EB2” is a smaller end mount for a ¾” bolt. The “EB3” is a larger end mount for a 1” bolt. See figure #4

Download Quick Reference Guides:

1. RP 643 TMC Air Suspension Maintenance Guidelines

Download PDF

Download PDF

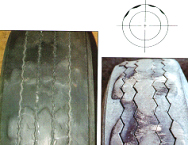

2. SAE Study 962152: Worn Shocks contribute to wheel hop and or greater tire load variance x4 = (+/- 80%)?, the primary effect of which is scalloped tires. Worn shocks are defined as those that have loss over half their dampening performance.

3. U.S. Department of Transportation and OECD / DEVINE analysis of Modern Truck Air Suspension found that once the shock worn past 50% dampening performance, road wear damage increased by over 20% as a result of increased air-ride tire load variance creating a jack-hammer type effect between the tire and pavement, in turn severely reducing tire life as well.

4. Hendrickson Trailer Air Suspension Maintenance Guidelines

Download PDF

Download PDF

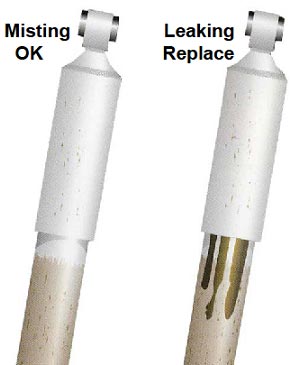

“Misting” shocks are often misdiagnosed asfailures. When a shock is subjected to rough roads, it’s fluid can become extremely hot. Under these conditions, small amounts of this hot fluid evaporate off of the piston rod while it’s under the dust cover. When the evaporated fluid reaches the cooler outside air, it condenses and forms a film or “mist”on the outside of the shock body. When mixed with road debris and dust, a large film of “hydraulic grime” will often form on the shock. This is a natural phenomenon caused by modern soft suspensions, and rough roads, and is not a failure.

A leaking shock is caused by a worn piston seal which allows fluid to escape from the top of the shock’s body. The fluid is pushed out with each extension, causing almost all of the fluid to escape in a short period of time. At the time inspection, leakers have usually lost all oftheir dampening. Unlike misting shocks, which generally show larges patches of film, a leaker may show signs of fluid that flowed in streams down the shock’s body. Evidence of these streams can most easily be seen when the shock is fully extended.

When the road gets rough, that is when you need your shocks the most! That why truck OEMs and Fleets rely on Gabriel to design shocks to resist fade due to heat created in severe conditions. Unlike competitive shocks, Gabriel shocks with HT fluid are uniquely design to work at 50% higher operating range. Gabriel HT fluid with viscosity additives helps maintain performance and does not begin to break down until 320 degrees vs. 220 degrees for AW fluid. In addition, Gabriel Heavy Truck shocks use a self-compensating metal spring-loaded piston ring for constant performance vs. a nylon piston sleeve found in automotive shocks that do not expand with temperature, allowing excessive blow -by as the fluid thins with heat. So while other shocks become ineffective, Gabriel is still working strong at high operating temperature. It is at these temperatures the thin film of hot fluid on the piston rod can evaporate off. As a result, misting will occasionally occur . This is a good thing!

Reagan Industries understand the challenges of ensuring your inventory covers your customers demands, yet does not unnecessarily tie up limited space and capitol. For this reason we offer low freight prepaid minimums and provide regular shock part number sales trend analysis to keep your inventory working for you.

Our reports provide both percentage of sales by part number and application, along with sales trend analysis.

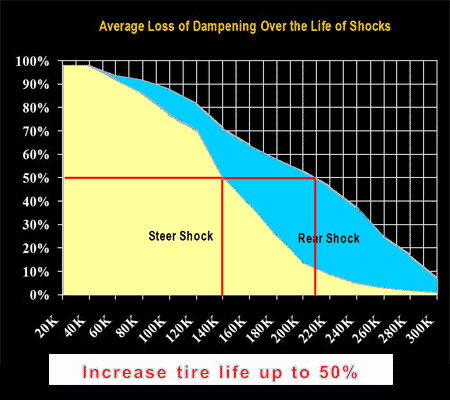

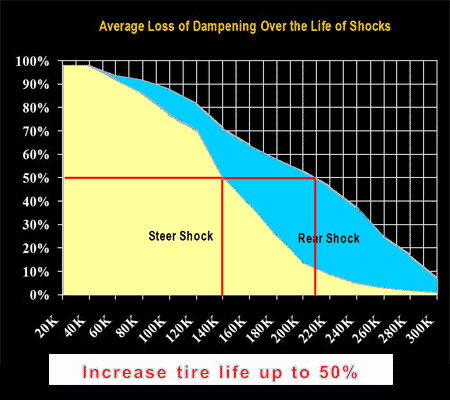

Shocks wear slowly over time and varies dependent upon operating environment. Worn shocks are defined as those that have lost over half their dampening performance, allowing for excessive wheel hop, permitting up to 4 times greater tire load variance. Average Life of Truck Shocks are 150,000 miles for Steer and 225,000 miles for rear.

The ATA-Truck Maintenance Council findings (RP643) reports that “Fleets have found it beneficial to install new shock absorbers when installing new tires, to maximize tire life.”

*U.S. Department of Transportation and OECD – DEVINE analysis of Modern Truck Air Suspension found that once the shock worn past 50% dampening performance, road wear damage increased by over 20% as a result of increased air-ride tire load variance creating a jack-hammer type effect between the tire and pavement, in turn severely reducing tire life as well.

*SAE Study 962152 “Worn Shocks contribute to wheel hop and or greater tire load variance x4 = (+/- 80%)”, the primary effect of which is scalloped tires. Worn shocks are defined as those that have loss over half their dampening performance.

*TMC RP#643 recommends that shocks be replaced on regular maintenance schedule, preferably at the same time tires are replaced. (See Industry Study Link)

Gabriel is the preferred OEM shock supplier to the North American trucking industry. You can count on Gabriel to provide the quality and ride control you need to achieve improved tire wear and lower maintenance costs.

Gas SLX Series – The most recent state of the art development in shock absorbers. Features include: 3 way adjustability, extreme high temperature fluid and seals designed to outlast normal shocks by up to 4 times under high temperature highway operating conditions. Gas cushioned in separate cells (not gas charged). This unique feature eliminates fade for the life of the shock and eliminates the inherent durability weaknesses of gas charged shocks.

83000-87000 Fleetline Series – Gabriel OE designed hydraulic shock. Get all the performance, durability and full application coverage with Gabriel Fleetline Shocks. These shocks are designed to meet stringent OEM specification. The different series represents various tensile demands and body sizes to accommodate increased fluid capacity and increased heat dissipation requirements.

G6000 Series –1 3/8” bore, gas charged, for light and medium sized truck and van applications. This series interchanges with the Monroe 34000, 36000 and 37000 series. Gabriel’s 9-stage valving provides a velocity sensitive smoother transition to rough road or terrain applications than Monroe’s grooved cylinder 2 stage “sensitrac” design.