Always add oil or grease to the inside of the sleeve and then firmly tighten. This will help prevent the sleeve from seizing to the bolt for future removal.

For ES-styles (those with pressed in sleeves): ALWAYS add oil or grease to the inside of the sleeve and then firmly tighten.

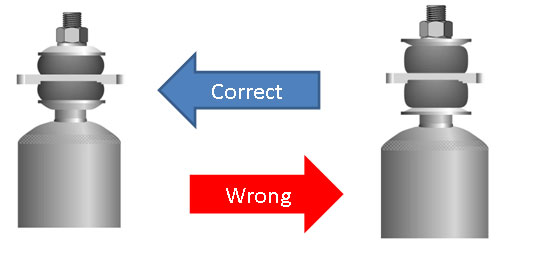

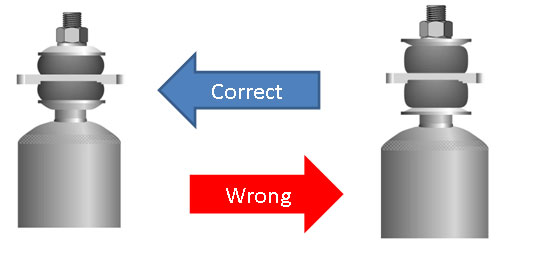

Don’t Over-tighten Split Bushings!! If the shock mount is over tightend and the bushing squeezed, there will be no side load pressure release and the shock will fail in a short period of time. ES style end mounts protects against this occurrence with the pressed metal sleeve in the bushing. However, extra care should always be taken not to over tighten split bushing type end mounts ( stud and EB styles). Always hand tighten these to the point shown in the following pictures.

Stud Mount: The washer should curve round the bushing and tightened to the point that it expands to the edge of the washer.

EB Mount: The washer should curve away from the bushing and tightened to no more that ¼” squeeze between washer and eye ring.

Use of Penetrating Oil should be applied as early as possible prior to removal. This is specifically important for ES Style end mounts which may need extra time for the oil to penetrate. We highly recommend “PB Blaster” as being the most effective.

Specific applications to take EXTRA CARE

Peterbilt Front use a shoulder bolt that steps down from ¾” to ⅝”. It has a tendency to break if removed with a pneumatic wrench. Always apply penetrating oil and use hand wrench for nut removal to avoid damage.

Volvo Front use a shoulder bolt that has fine metric threads. Caution should be used to not strip the threads. Use penetrating oil and hand wrench for nut removal.