Cemera Part industries, in partnership with our vendors have produced training and marketing material to support our customers.

This includes training videos (viewable with log in), posters, counter mats, and Spanish literature

Other vendor literature available for distribution includes:

Gabriel

Gabriel

- E-Catalog

- Gabriel Shock Brochure (SP-0848)

- Counter Mat

Goodyear Wiper Blade

Goodyear Wiper Blade

- Catalog

- Assurance Beam Blade Brochure

- Display Racks Available

Firestone

Firestone

- E-Catalog

- Air Spring E-Catalog (Spanish)

- Ride-Rite Brochure

Tramec Sloan

Tramec Sloan

Tru-Balance

Tru-Balance

- Catalog

- Brochure (tri-fold)

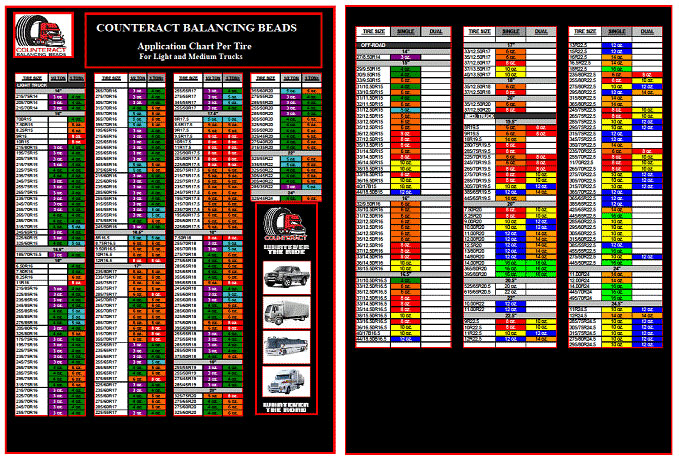

Counteract Balancing

Counteract Balancing

- Brochure

- Application Chart

- 2.2% Fuel Economy PAVE Sheet Sticker

Truck-Lite

Truck-Lite

H.D.M Exhaust

H.D.M Exhaust

Heavy Duty Manf. Catalog

Heavy Duty Manf. Catalog

Goodyear Air Springs

Goodyear Air Springs

Continental Belts & Hose

Continental Belts & Hose

Gabriel is the preferred OEM shock supplier to the North American trucking industry. You can count on Gabriel to provide the quality and ride control you need to achieve improved tire wear and lower maintenance costs.

Gas SLX Series – The most recent state of the art development in shock absorbers. Features include: 3 way adjustability, extreme high temperature fluid and seals designed to outlast normal shocks by up to 4 times under high temperature highway operating conditions. Gas cushioned in separate cells (not gas charged). This unique feature eliminates fade for the life of the shock and eliminates the inherent durability weaknesses of gas charged shocks.

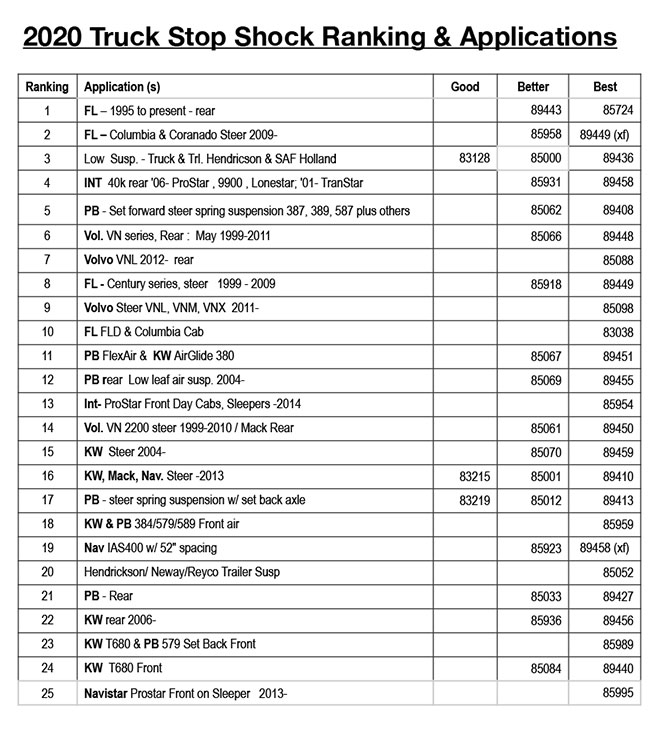

83000-87000 Fleetline Series – Gabriel OE designed hydraulic shock. Get all the performance, durability and full application coverage with Gabriel Fleetline Shocks. These shocks are designed to meet stringent OEM specification. The different series represents various tensile demands and body sizes to accommodate increased fluid capacity and increased heat dissipation requirements.

G6000 Series –1 3/8” bore, gas charged, for light and medium sized truck and van applications. This series interchanges with the Monroe 34000, 36000 and 37000 series. Gabriel’s 9-stage valving provides a velocity sensitive smoother transition to rough road or terrain applications than Monroe’s grooved cylinder 2 stage “sensitrac” design.

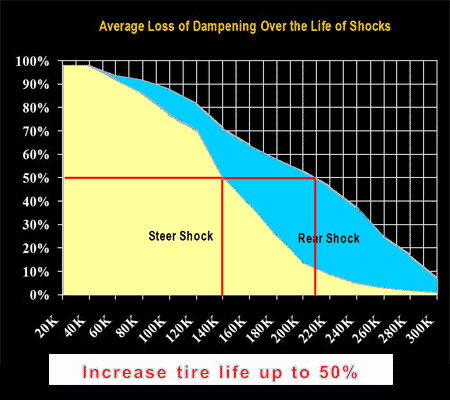

Shocks wear slowly over time and varies dependent upon operating environment. Worn shocks are defined as those that have lost over half their dampening performance, allowing for excessive wheel hop, permitting up to 4 times greater tire load variance. Average Life of Truck Shocks are 150,000 miles for Steer and 225,000 miles for rear.

The ATA-Truck Maintenance Council findings (RP643) reports that “Fleets have found it beneficial to install new shock absorbers when installing new tires, to maximize tire life.”

*U.S. Department of Transportation and OECD – DEVINE analysis of Modern Truck Air Suspension found that once the shock worn past 50% dampening performance, road wear damage increased by over 20% as a result of increased air-ride tire load variance creating a jack-hammer type effect between the tire and pavement, in turn severely reducing tire life as well.

*SAE Study 962152 “Worn Shocks contribute to wheel hop and or greater tire load variance x4 = (+/- 80%)”, the primary effect of which is scalloped tires. Worn shocks are defined as those that have loss over half their dampening performance.

*TMC RP#643 recommends that shocks be replaced on regular maintenance schedule, preferably at the same time tires are replaced. (See Industry Study Link)

Reagan Industries understand the challenges of ensuring your inventory covers your customers demands, yet does not unnecessarily tie up limited space and capitol. For this reason we offer low freight prepaid minimums and provide regular shock part number sales trend analysis to keep your inventory working for you.

Our reports provide both percentage of sales by part number and application, along with sales trend analysis.

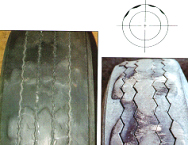

Scalloped – Cupping Damage:

Primary type wear experienced with worn shocks. Loss of shock dampening allows for greater tire load variance and allows build up of resonance with the rhythm of a road quickly resulting in cupping wear. Tire companies can measure early scalloped cupping in new truck tires on older shocks within a few hundred miles on a rough road; however, the same test conducted with new tires and new shocks does not experience similar damage for tens of thousands of miles. This can impact the life of the tire as much as 50%. For this reason, it has been found cost effective to change shocks when replacing tires on modern Heavy Truck suspensions.

River or Channel Wear:

Tests (driven by results of the SAE Study) identified the cause of River Channel Wear due to the loss of shock absorber dampening , allowing excessive footprint distortion. This creates excessive wear along the sides of the tread pattern where the rubber that can move the easiest.

Brake Lock Up Wear:

Worn shocks can contribute to brake lock up causing uneven wear. If the suspension had been in resonance with the rhythm of the road allowing the tires inconsistent road traction, prior to an emergency braking situation, a brake lock up situation can easily occur.

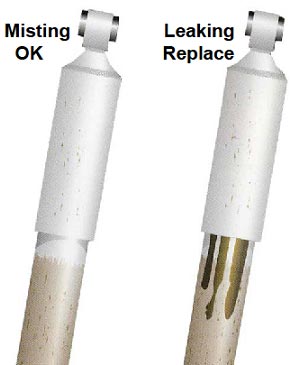

“Misting” shocks are often misdiagnosed asfailures. When a shock is subjected to rough roads, it’s fluid can become extremely hot. Under these conditions, small amounts of this hot fluid evaporate off of the piston rod while it’s under the dust cover. When the evaporated fluid reaches the cooler outside air, it condenses and forms a film or “mist”on the outside of the shock body. When mixed with road debris and dust, a large film of “hydraulic grime” will often form on the shock. This is a natural phenomenon caused by modern soft suspensions, and rough roads, and is not a failure.

A leaking shock is caused by a worn piston seal which allows fluid to escape from the top of the shock’s body. The fluid is pushed out with each extension, causing almost all of the fluid to escape in a short period of time. At the time inspection, leakers have usually lost all oftheir dampening. Unlike misting shocks, which generally show larges patches of film, a leaker may show signs of fluid that flowed in streams down the shock’s body. Evidence of these streams can most easily be seen when the shock is fully extended.

When the road gets rough, that is when you need your shocks the most! That why truck OEMs and Fleets rely on Gabriel to design shocks to resist fade due to heat created in severe conditions. Unlike competitive shocks, Gabriel shocks with HT fluid are uniquely design to work at 50% higher operating range. Gabriel HT fluid with viscosity additives helps maintain performance and does not begin to break down until 320 degrees vs. 220 degrees for AW fluid. In addition, Gabriel Heavy Truck shocks use a self-compensating metal spring-loaded piston ring for constant performance vs. a nylon piston sleeve found in automotive shocks that do not expand with temperature, allowing excessive blow -by as the fluid thins with heat. So while other shocks become ineffective, Gabriel is still working strong at high operating temperature. It is at these temperatures the thin film of hot fluid on the piston rod can evaporate off. As a result, misting will occasionally occur . This is a good thing!

1. RP 643 TMC Air Suspension Maintenance Guidelines

2. SAE Study 962152: Worn Shocks contribute to wheel hop and or greater tire load variance x4 = (+/- 80%)?, the primary effect of which is scalloped tires. Worn shocks are defined as those that have loss over half their dampening performance.

3. U.S. Department of Transportation and OECD / DEVINE analysis of Modern Truck Air Suspension found that once the shock worn past 50% dampening performance, road wear damage increased by over 20% as a result of increased air-ride tire load variance creating a jack-hammer type effect between the tire and pavement, in turn severely reducing tire life as well.

4. Hendrickson Trailer Air Suspension Maintenance Guidelines

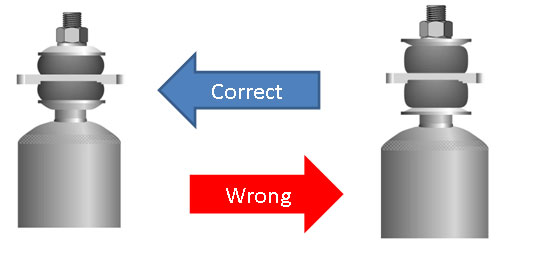

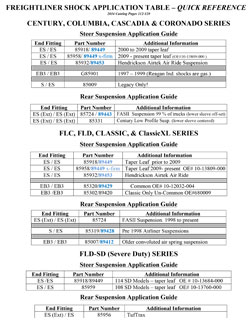

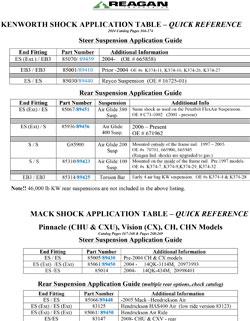

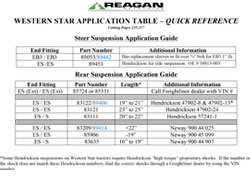

The Reagan Ind. Shock Absorber Quick Reference Application sheets use end mount codes as one of the key indicators for identifying the correct replacement shock. The five end mount codes used on these sheets are as follows:

“S” for Stud. The shock is mounted with a vertical Stud, rather than an eye ring. See figure #1

“ES” stands for E for eye ring, and S for sleeve. A steel sleeve is attached between two factory pressed in bushings. See figure #2

“ES (Ext)” is the same as “ES”, only the sleeve is extended out from the bushing. See figure #3. Note that this end mount identification is used only for the purposes of the Quick Reference Application Sheets, and is not referenced in the Gabriel catalog.

“EB2” & “EB3” E again stands for Eye ring, and B stands for Bushing. There is no sleeve. The mounting bolt fits directly into the bushings, which are held in place by washers. The Gabriel shock bushings are separate. The “EB2” is a smaller end mount for a ¾” bolt. The “EB3” is a larger end mount for a 1” bolt. See figure #4

Download Quick Reference Guides:

The benefits of balancing the steer tires are well recognized within the industry. Balanced tires reduce rolling resistance by decreasing tire sidewall flexing, tread squirming and friction and help prevent cupping. Studies show tire operating temperatures of balanced tire to run 8-25% cooler (dependent upon type of balancing system) than un-balanced tire.

So why not also balance the drive and trailer tires? For rear and dual tires, the whole wheel assembly needs to balanced together and centered perfectly. The same vibration that the driver feels on the Steer tires also applies to the drive and trailer and is multiplied by the tolerance imperfections of the duel wheel assembly. Unchecked, it is one of the main reasons for wheel fasteners, U-bolts, and torque rod bolts to work themselves loose. The best means to avoid this and improve tire wear and fuel economy through decreased roll resistance is with a dynamic balancing system, such as Counteract.

Counteract bags are color coded for different oz. quantity for easy identification.

There are a lot of dynamic tire balancing products in the market. Reagan industries has taken a close look at them all. Only Counteract provided Industry Standard Third Party Testing that gave us the confidence to offer this product to our customers. We believe you will find it a clean, easy to use, cost effective product that will help the bottom line of your fleet customers.

University of Brazil – Commercial Tire Tread & Tire Temp Evaluation. Results showed that tires balanced with Counteract showed an average 12.8% greater life than non-balanced at all tire positions (truck & trailer). In addition tires balanced with Counteract ran on average 9% cooler than non-balanced tires and 15% cooler than a competitive dynamic balanced using an outer-ring attached to the wheel. At highway speed the Counteract was 10% and 19% cooler respectively.

PAVE – Auburn University TMC/SAE Type II fuel economy test performed on fully loaded tractor trailers in which all wheel positions were balanced using Counteract Balancing Beads, showed a 2.2% improvement in fuel economy (At 100,000 miles per year, that’s over 250 gallons of diesel)

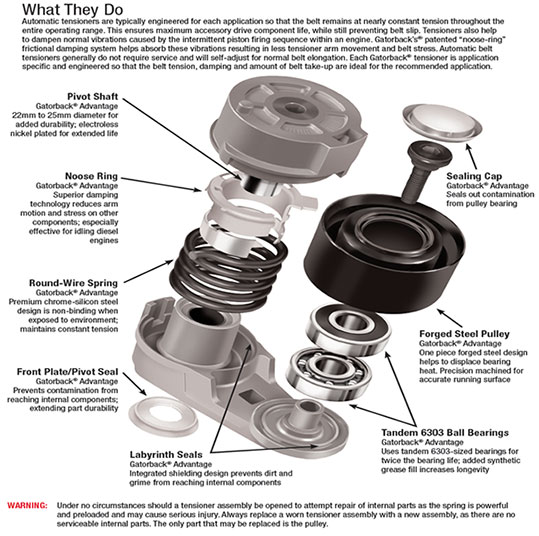

Reagan Industries offers a comprehensive coverage Continental OE Quality Mileage Maker Belts,Continental’s special designed Continental Elite Belts as well as the tensioners and pulleys to ensure peak performance

Construction:

Poly-V Belt EPDM Cushion Rib Compound: (EPDM) belts far outlast and outperform their predecessors, rarely showing cracks and, even at very high mileage.

V-Belt Wingprene® Cushion & Cog Compound: impregnated with Wingprene® oil resistant rubber to reduce surface fatigue, resists cracking.

Polyester Fiber with High strength Vytacord®: maintain tension integrity during belt service life, by reducing stretch while still maintaining flexibility.

Straight – Ribbed Design

Abrasion, Oil and Chemical resistant

Packaging: Includes competitive cross references for easy identification and replacement.

Advanced Technology For Improved Performance

Construction:

Quiet Channel Technology: Advanced materials virtually eliminate the usual noise caused by serpentine belt misalignment.

Greater Wear Resistance: High strength materials maintain tension integrity during belt service life, by reducing stretch.

Exceptional Belt Life: Advanced materials create a more flexible and cooler running belt, greatly extending the belt life.

SAE Specifications: SAE J1459

Standard Style

Continental Elite with/Quiet Channel Technology:

Advanced variable cog pattern practically eliminates noise and slippage.

Continental Elite to Mileage Maker Cross Ref

Poly-V:

Both the Continental Elite and Mileage Maker part numbers are derived by the number of ribs and belt length. Continental simply changed the order in which the information is given.

For example a Continental Elite 4081065 is a Mileage Maker 1065K8MK

- The Continental Elite first digit identifies the type of belt it is the number 4 represents a K section Poly- V Belt

- 08 represents number of ribs

- 1065 represents length. The 106 is inches and the last digit “5” is number of tenths of an inch. In this case it is 106 5/10″

- MK” simply indicates Mileage Maker

V-Belts:

In most cases, the Mileage Maker number will either use the same number, or the closest number ending in either a “0” or “5”, followed by “MK” for Mileage Maker. For example- Continental Elite 17511 crosses to a Mileage Maker 17510MK.

Gabriel is the preferred OEM shock supplier to the North American trucking industry. You can count on Gabriel to provide the quality and ride control you need to achieve improved tire wear and lower maintenance costs.

Gas SLX Series – The most recent state of the art development in shock absorbers. Features include: 3 way adjustability, extreme high temperature fluid and seals designed to outlast normal shocks by up to 4 times under high temperature highway operating conditions. Gas cushioned in separate cells (not gas charged). This unique feature eliminates fade for the life of the shock and eliminates the inherent durability weaknesses of gas charged shocks.

83000-87000 Fleetline Series – Gabriel OE designed hydraulic shock. Get all the performance, durability and full application coverage with Gabriel Fleetline Shocks. These shocks are designed to meet stringent OEM specification. The different series represents various tensile demands and body sizes to accommodate increased fluid capacity and increased heat dissipation requirements.

G6000 Series –1 3/8” bore, gas charged, for light and medium sized truck and van applications. This series interchanges with the Monroe 34000, 36000 and 37000 series. Gabriel’s 9-stage valving provides a velocity sensitive smoother transition to rough road or terrain applications than Monroe’s grooved cylinder 2 stage “sensitrac” design.

The benefits of balancing the steer tires are well recognized within the industry. Balanced tires reduce rolling resistance by decreasing tire sidewall flexing, tread squirming and friction and help prevent cupping. Studies show tire operating temperatures of balanced tire to run 8-25% cooler (dependent upon type of balancing system) than un-balanced tire.

So why not also balance the drive and trailer tires? For rear and dual tires, the whole wheel assembly needs to balanced together and centered perfectly. The same vibration that the driver feels on the Steer tires also applies to the drive and trailer and is multiplied by the tolerance imperfections of the duel wheel assembly. Unchecked, it is one of the main reasons for wheel fasteners, U-bolts, and torque rod bolts to work themselves loose. The best means to avoid this and improve tire wear and fuel economy through decreased roll resistance is with a dynamic balancing system, such as Counteract.

Reagan Industries offers a comprehensive coverage Continental OE Quality Mileage Maker Belts,Continental’s special designed Continental Elite Belts as well as the tensioners and pulleys to ensure peak performance

Gabriel is the preferred OEM shock supplier to the North American trucking industry. You can count on Gabriel to provide the quality and ride control you need to achieve improved tire wear and lower maintenance costs.

Gas SLX Series – The most recent state of the art development in shock absorbers. Features include: 3 way adjustability, extreme high temperature fluid and seals designed to outlast normal shocks by up to 4 times under high temperature highway operating conditions. Gas cushioned in separate cells (not gas charged). This unique feature eliminates fade for the life of the shock and eliminates the inherent durability weaknesses of gas charged shocks.

83000-87000 Fleetline Series – Gabriel OE designed hydraulic shock. Get all the performance, durability and full application coverage with Gabriel Fleetline Shocks. These shocks are designed to meet stringent OEM specification. The different series represents various tensile demands and body sizes to accommodate increased fluid capacity and increased heat dissipation requirements.

G6000 Series –1 3/8” bore, gas charged, for light and medium sized truck and van applications. This series interchanges with the Monroe 34000, 36000 and 37000 series. Gabriel’s 9-stage valving provides a velocity sensitive smoother transition to rough road or terrain applications than Monroe’s grooved cylinder 2 stage “sensitrac” design.

The benefits of balancing the steer tires are well recognized within the industry. Balanced tires reduce rolling resistance by decreasing tire sidewall flexing, tread squirming and friction and help prevent cupping. Studies show tire operating temperatures of balanced tire to run 8-25% cooler (dependent upon type of balancing system) than un-balanced tire.

So why not also balance the drive and trailer tires? For rear and dual tires, the whole wheel assembly needs to balanced together and centered perfectly. The same vibration that the driver feels on the Steer tires also applies to the drive and trailer and is multiplied by the tolerance imperfections of the duel wheel assembly. Unchecked, it is one of the main reasons for wheel fasteners, U-bolts, and torque rod bolts to work themselves loose. The best means to avoid this and improve tire wear and fuel economy through decreased roll resistance is with a dynamic balancing system, such as Counteract.

Reagan Industries offers a comprehensive coverage Continental OE Quality Mileage Maker Belts,Continental’s special designed Continental Elite Belts as well as the tensioners and pulleys to ensure peak performance

Air Springs

Reagan Industries is the industry leader in providing full air spring coverage and application support. We are proud to offer both Firestone and Goodyear Air Springs for all your truck, trailer, and bus needs.

Air Spring suspensions offer greater degree of durability and protection of the cargo, vehicle and reduction of driver fatigue. Air Springs isolate vibration, reducing cab, trailer and cargo damage. In conjunction with leveling valves, it maintains constant ride height and trim. This leads to improved tire wear of approximately 13% over multi-leaf suspensions.

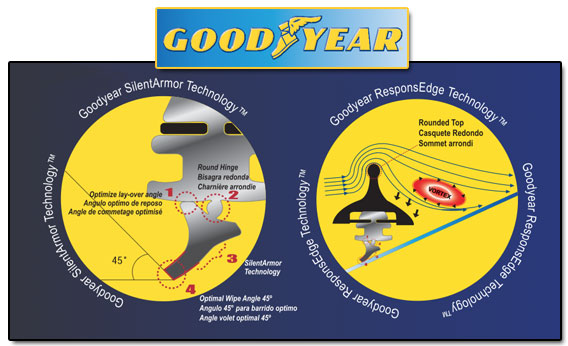

Wiper Blades

Unlike other brands that are moving overseas, Goodyear Wiper Blades are 100% made in the USA with all steel construction, and superior Goodyear rubber formulated especially for wiper blades. This gives these blades longer streak free use. So if you are tired of replacing your blades after just a few month do to streaking or sticking to the windshield because of low quality Chinese rubber, save time, money and eye strain with Premium Goodyear Blades!

728 Premium Blade

Most common design for past ten years. Uses Heavy Duty steel frame with reinforced joints and multi-coat paint protection along with SilentArmor Rubber Technology

770 Hybrid Blade

Newest and most advanced design. The Hybrid blades combines the beam blade steel flexor for superior pressure points, rugged durability of the standard frame, covered by a resin wind spoiler frame designed to create Uniform Windshield Contact. With no exposed frame to collect snow and ice, it is an excellent ALL-Season blade.

758 Winter Blade

Same great 728 blade but with an added rubber boot to cover the frame to avoid snow and ice build up. For no real cost difference we recommend the 765 blade for All-Season superior performance

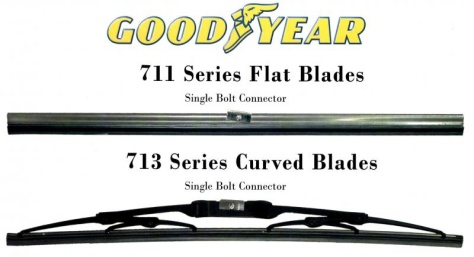

711 & 713 Single Bolt Connection

Older Style blades many time used on Trucks with Duel Windshields as well as popular in the Marine market. Flat Style come in 11”-22” lengths 713 Curved Style come 13”, 15”, 16”, 18”, and 22” lengths

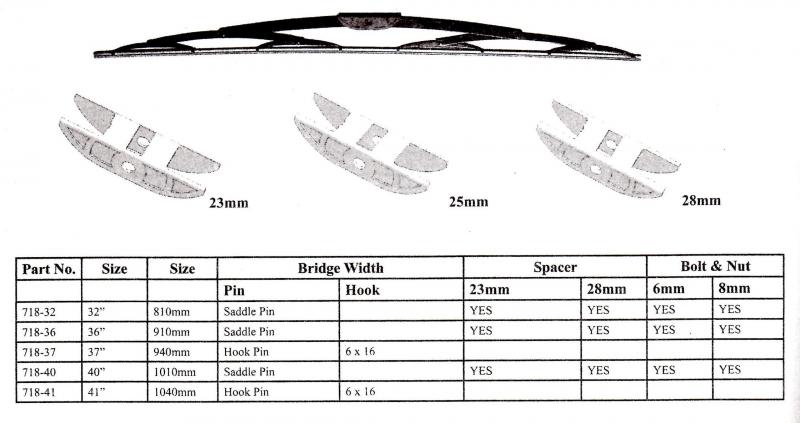

717 & 718 Series (single bolt with spacers)

Primarily used on Coaches, RV, and Bus applications. Length range from 21”-41”